Epoxy Garage Floors and Epoxy Flooring Solutions at Epoxy Garage Floors Montgomery

Introduction

Epoxy Garage Floors Montgomery offers Epoxy flooring systems that are renowned for their durability, aesthetic appeal, and protective qualities, making them an ideal choice for various environments, from residential garages to commercial spaces. We’ll dive into the specifics of epoxy garage floors and broader epoxy flooring applications, highlighting their benefits, installation processes, and maintenance tips.

What is Epoxy Flooring?

Epoxy is a term for materials made from a combination of resins and hardeners. When mixed, they chemically react to form a rigid plastic material that is strong, resistant to degradation, and bonds exceptionally well to its substrate. Epoxy flooring is essentially a surface coating that includes multiple layers of epoxy applied to a floor with a depth of at least two millimeters.

Advantages of Epoxy Flooring

The popularity of epoxy flooring can be attributed to several key features:

Durability

Epoxy coatings transform ordinary floors into non-porous surfaces that can withstand high traffic, heavy impact, and harsh chemicals, making them perfect for garages, workshops, and commercial kitchens.

Aesthetic Variety

Epoxy floors offer an array of decorative options, including a variety of colors and textures. They can mimic the appearance of granite, quartz, or even more intricate designs, enhancing the visual appeal of living rooms, kitchens, and commercial spaces.

Safety

Epoxy coatings are resistant to slippage, temperature, impact, and fire, promoting safety in environments like aircraft hangars and pool decks.

Ease of Maintenance

The seamless surface of epoxy floors makes them easy to clean and disinfect, which is vital in settings that require impeccable hygiene, such as hospitals and clinics.

Installation of Epoxy Flooring

The installation of an epoxy floor coating involves several steps that must be meticulously followed to ensure optimal adhesion and performance:

- Surface Preparation: The substrate must be clean, dry, and free of any contaminants or imperfections. This stage might involve diamond grinding, shot blasting, or chemical treatments.

- Priming and Patching: A primer is applied, followed by patching of any cracks or chips in the concrete.

- Mixing and Applying Epoxy: The epoxy resin and hardener are mixed according to manufacturer specifications. The mixture is then applied in layers, using brushes or rollers.

- Curing: The epoxy must cure for several days before the floor can be fully used. During this time, the floor should not be exposed to excessive heat or moisture.

Maintenance Tips

Maintaining an epoxy floor is straightforward but essential:

- Regular cleaning with a mop and mild detergent will keep the floor looking new.

- Avoid using abrasive cleaning tools or harsh chemicals that could damage the surface.

- Periodic resealing may be necessary to maintain the floor’s luster and protective qualities.

Applications of Epoxy Flooring

Beyond garages, epoxy flooring extends to diverse applications such as residential areas, commercial buildings, and specialty applications like aircraft hangars and pool decks. Each setting demands specific types of epoxy coatings that cater to the unique needs of the environment.

Conclusion

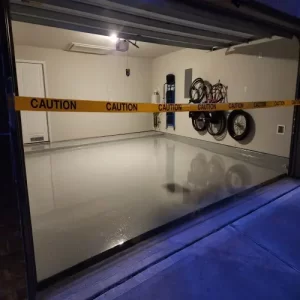

Epoxy flooring offers a versatile and durable solution for many different environments, combining aesthetics with functionality. Whether you are upgrading your home garage or outfitting a large commercial facility, epoxy provides a reliable flooring solution that stands up to the demands of daily use. To view some completed projects and see the potential transformations epoxy flooring can offer, visit Epoxy Garage Floors Montgomery’s gallery.