Living in Magnolia and the surrounding communities of Montgomery County means enjoying mature trees, big yards and a close‑knit community. It also means dealing with heat, humidity and clay soils that can be hard on concrete driveways. Homeowners often wonder whether a concrete driveway repair will buy more time or whether replacement is the wiser investment. This guide compares repair and replacement for concrete driveway repair Magnolia TX, outlines how to assess crack width and depth, and explains why the decision matters in Magnolia’s climate.

Why driveways fail in Magnolia’s climate

Concrete has been used for decades because it is strong and long‑lasting. Yet even good slabs develop cracks over time. A‑1 Concrete Leveling notes that hairline cracks are superficial and can usually be sealed, while large cracks that cause crumbling often indicate that the slab’s integrity has been compromised. Several factors contribute to concrete distress in Magnolia:

-

Shrinkage and expansion. Hot summers cause concrete and clay subgrades to shrink; cool, wet winters cause expansion. HydroHelp911 explains that hairline cracks (<1/16 in) are often the result of drying shrinkage and are not structural, whereas structural cracks are wider (≥ 1/4 in) and run through the thickness of the slab.

-

Soil movement. Magnolia sits on expansive clay that swells when wet and shrinks when dry. Poor compaction or inadequate base thickness causes driveways to settle unevenly. The local contractor’s guide to building driveways advises compacting the clay subgrade with a plate compactor until the surface rebounds less than 1/4 in under foot pressure, noting that this density prevents later settlement when Magnolia’s clay shrinks during summer droughts.

-

Drainage and tree roots. Heavy rain is common; climate data show Magnolia receives 4.28 in of rain in July with about 12 rainy days. Without a slope of about ¼ in per foot away from the garage, puddles linger and the slab experiences freeze–thaw cycles. Roots from live oaks and pines also push on slab edges.

These environmental stresses produce different crack types. Determining whether the damage is superficial or structural is the first step in deciding between patching and replacement.

Inspecting crack width and depth

Cracks are assessed by their width and depth. A crack gauge or simple ruler can provide a quick measure. Based on industry guidelines and research from A‑1 Concrete and HydroHelp911, cracks fall into several categories:

| Crack width (inches) | Typical depth | Likely cause | Suggested action |

|---|---|---|---|

| < 1/16 in (hairline) | Often shallow (top ⅓ of slab) | Shrinkage during curing; minor settlement | Seal with flexible concrete caulk or epoxy injection to keep out moisture. |

| 1/16 – 1/8 in | Shallow or moderate | Slight settlement or temperature change | Seal and monitor; if movement is noticed, consider crack stitching. |

| 1/8 – 1/4 in | May extend through slab | Load‑induced stress or subgrade movement | Crack stitching (installing carbon‑fiber stitches) to prevent widening; partial‑depth removal and patching if spalling occurs. |

| > 1/4 in | Often through slab or multiple cracks | Structural failure or base erosion | Partial‑depth repair if deterioration is confined to top 1/3; full replacement if cracks extend deep or there is widespread crumbling. |

Measuring depth

Depth is judged by removing a small section of concrete around the crack or by using a borescope. The Federal Highway Administration explains that partial‑depth repair is appropriate when deterioration is limited to the top one‑third of the slab. When cracks penetrate deeper than one‑third or are located near joints, full‑depth replacement is required.

Repair options and when they work

The goal of repair is to stop water infiltration, restore load capacity and improve appearance. Repair makes sense when cracks are relatively narrow, the subbase is sound and the driveway is not near the end of its life (20+ years). Local contractor Concrete Contractor Magnolia (CCM) emphasises that they use only high‑quality materials and engineer‑recommended components such as 3/8 in rebar and 3500 PSI concrete to strengthen repair areas. For more information about common repairs, see CCM’s concrete repair page. They advise a thorough inspection of the damaged area to determine the appropriate repair approach. The following methods address different severities of damage:

Sealing hairline and small cracks

-

Caulking with flexible sealant or epoxy injection. A‑1 Concrete Leveling notes that hairline cracks can usually be sealed with flexible concrete caulk; structural cracks causing crumbling generally require replacement. HydroHelp911 adds that injecting epoxy or polyurethane into hairline cracks bonds the sides, prevents water intrusion and stops mold and pests. Surface sealants should be applied afterward to ensure moisture control.

-

Cost considerations. DIY sealing materials cost about $10–$12 per tube of quality concrete caulk. Hiring a professional to fill cracks typically ranges from $100 to $1,000 depending on the number of cracks and preparation required.

Crack stitching for moderate cracks

When cracks exceed roughly 1/8 in or show slight vertical movement but the slab is otherwise sound, crack stitching stabilises the concrete. Straightline Pier explains that technicians saw‑cut small channels perpendicular to the crack and insert carbon‑fiber strips bonded with epoxy; these stitches redistribute tension, prevent widening and protect against water infiltration. This solution is cost‑effective compared to replacing the entire slab and can be completed quickly with minimal disruption.

Partial‑depth patching for spalls and scaling

Spalling occurs when the top surface delaminates or flakes off, often due to freeze–thaw cycles or inadequate curing. The FHWA guidelines say partial‑depth repair is used for removing deteriorated concrete in the upper 1–2 in of the slab and is appropriate for spalls less than 6 in long and 1.5 in wide. The damaged section is cut and cleaned; new concrete is bonded into place. This technique is also useful for repairing edges broken by heavy vehicles.

Lifting and slab jacking

Uneven slabs caused by soil settlement can often be corrected without replacement. Contractors drill small holes and inject a cementitious or polyurethane slurry beneath the slab to raise it back to its original elevation. This method is less invasive and costs considerably less than replacement. However, if the slab is cracked into multiple pieces or the base is unstable, lifting may not be sufficient.

When replacement is the better choice

Concrete driveways generally last 25–30 years with proper construction and maintenance. Several circumstances warrant replacement rather than continued repairs:

-

Severe or widespread cracking. Structural cracks wider than 1/4 in or multiple long cracks that intersect indicate that the slab no longer acts as a single unit. The FHWA recommends full‑depth replacement when distress extends deeper than one‑third of the slab or when deterioration is near joints. Cross‑stitching cannot restore the structural capacity of such slabs.

-

Settled or heaved slabs. If part of the driveway has sunk several inches or heaved up due to tree roots or expansive soil, patching the cracks may not address the underlying cause. A stable base must be re‑established by removing the old slab, correcting drainage and compaction, and pouring new concrete.

-

Old age and wear. Driveways over 20 years old often show surface scaling, multiple repairs and general wear. In such cases, resurfacing or replacement may improve performance and aesthetics more effectively than patchwork.

-

Major design changes. Homeowners who wish to widen a driveway, add decorative finishes or change the alignment often choose replacement. CCM’s driveway page highlights unique finishes such as staining, stamping and textured surfaces that add elegance and durability.

Replacement process and local best practices

Building a durable driveway in Magnolia requires attention to site conditions and climate. The detailed construction guide provided by CCM outlines the steps to follow:

-

Plan drainage and traffic flow. Walk the site after a rainstorm to see where water collects. The finished surface should slope about ¼ in per foot toward the street. Consider turning radii for trucks and trailers to prevent tires from climbing curbs and cracking corners.

-

Layout and grade. Drive stakes at each corner and stretch mason’s lines to the proposed surface height. Measure both diagonals so the rectangle stays square, then set the string lines 1 in below the garage floor to keep water outside.

-

Excavate and compact the subgrade. Remove sod, roots and topsoil until the required depth equals slab thickness plus 6 in for base material. Compact Magnolia’s clay using a vibratory plate compactor until the surface rebounds less than ¼ in under foot pressure. This density prevents settlement when the soil dries.

-

Install a stable granular base. Spread 4–6 in of crushed limestone, dampen and compact it in two lifts. The granular layer drains quickly during storms and spreads wheel loads evenly.

-

Build straight, plumb forms and place rebar. Use 2×6 boards on edge for a 5‑in slab, or 2×8 boards where heavy pickups or RVs will park. Brace forms every 3 ft and maintain uniform slope. Space 3/8 in rebar 16 in on center in both directions and support it on 2 in chairs so steel sits in the lower third of the slab.

-

Order an appropriate concrete mix and manage heat. Request a 3,500 PSI mix with 5 % entrained air and admixtures to slow hydration when temperatures exceed 85 °F. Schedule the pour for early morning and cool the subgrade, forms and reinforcement with water to keep concrete temperature below 95 °F.

-

Place, strike off and finish. Discharge the mix directly from the truck into the forms, screed to match the form edges and use a bull float to embed aggregate. After bleed water evaporates, edge the perimeter and cut control joints to ¼ of the slab depth at 10 ft intervals to provide predetermined crack locations.

-

Cure properly. Keep the surface moist for at least seven days by misting, covering with burlap or using a curing compound. Proper curing helps the concrete reach its design strength and reduces shrinkage cracking.

Following these steps, along with proper subgrade preparation and reinforcement, yields a driveway that lasts decades. CCM emphasises that using 3500 PSI concrete and 3/8 in rebar ensures the driveway is built to withstand heavy loads and the test of time.

Cost comparison: repair vs. replacement

Budget plays a significant role in the repair/replace decision. Here are typical cost ranges based on 2025 data:

Repair costs

-

Sealing hairline cracks: DIY caulk or epoxy injection can cost as little as $5–$15, while hiring a professional may range from $100 to $1,000 depending on the number and length of cracks.

-

Resurfacing: Applying a new overlay to refresh a surface costs roughly $5–$80 for DIY materials, or $2,000–$5,000 for professional resurfacing on a standard driveway. This is often done when the base is sound and the surface has widespread scaling.

-

Slab lifting: Lifting uneven slabs with polyurethane injection ranges from $500 to $6,000 depending on the extent of settlement.

HomeAdvisor reports that the normal range for concrete driveway repair is $828–$2,820, with an average of $1,795 in 2025.

Replacement costs

Replacing a driveway is more expensive but yields a completely new surface. HomeGuide’s June 2025 report states that a concrete driveway costs $6–$15 per square foot or $2,400–$8,600 on average for a two‑car driveway. The price varies with finish quality:

-

Standard (plain gray): $6–$10 per square foot.

-

Basic decorative (single‑color stain or exposed aggregate): $10–$15 per square foot.

-

Mid‑range decorative (stamped patterns, multi‑color stains): $15–$20 per square foot.

-

High‑end custom (complex patterns, custom borders): $20–$25+ per square foot.

These costs include demolition of the existing slab, base preparation, reinforcement, concrete, finishing and curing. Additional costs apply for drainage improvements, tree root removal or driveway extensions. CCM’s promotional materials advertise starting prices of about $9.99 per square foot for new driveways, demonstrating that local contractors offer competitive rates.

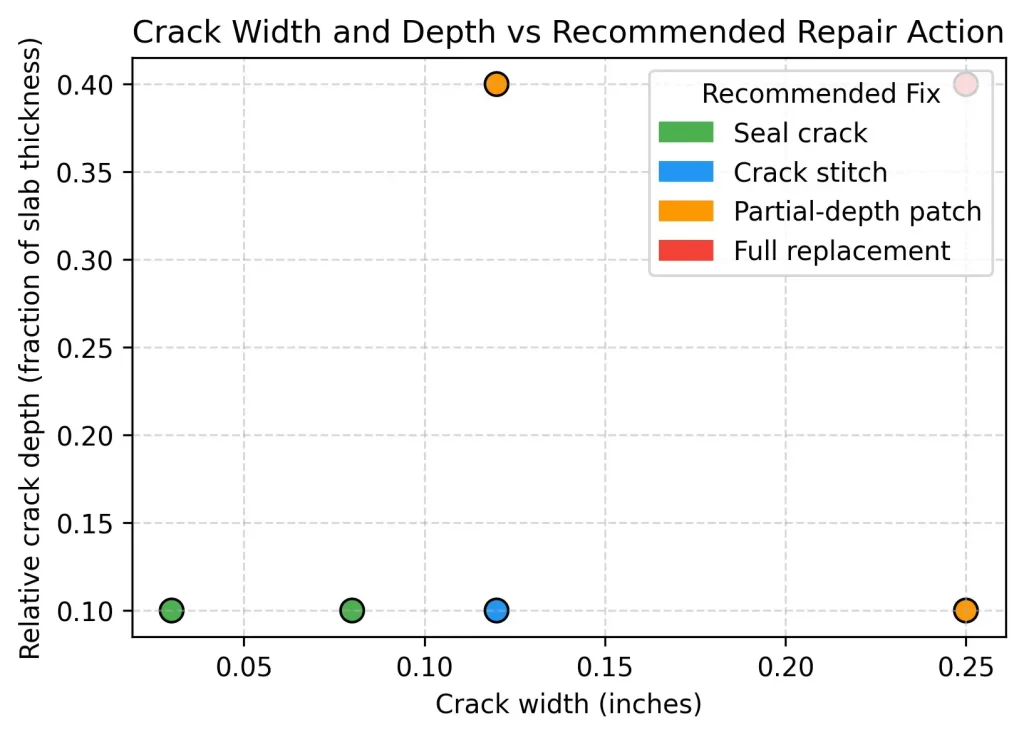

Crack width/depth vs. recommended fix

The relationship between crack size and the appropriate repair method can be visualised in a chart. The following scatter plot plots crack width against relative depth (fraction of slab thickness) and uses colour to indicate the recommended fix. Hairline cracks (green) are best sealed; moderate cracks (blue) may require crack stitching; deeper or wider cracks (orange and red) necessitate partial‑depth patches or full replacement.

The chart shows that as width and depth increase, the recommended repair becomes more intensive. Cracks wider than ¼ in and deeper than one‑third of the slab usually require full replacement or partial removal because the structure has lost its integrity. In contrast, hairline cracks at the surface can often be sealed, halting moisture ingress and preventing escalation. Crack stitching provides an intermediate solution for cracks around ⅛ in where the slab is still structurally sound.

How Magnolia’s local expertise adds value

Choosing a local contractor familiar with Magnolia’s soil and climate makes a significant difference. CCM emphasises several practices that align with industry recommendations:

-

Proper subgrade preparation: The team emphasises compacting or replacing soil until bearing capacity is right for the load, not guessing.

-

Laser‑set elevations and accurate forms: Forms follow laser‑set elevations rather than manual estimates, ensuring correct slope for drainage.

-

Rebar at the correct height: Reinforcement sits at the correct height (not buried in dirt) to provide structural strength.

-

Mix matched to use: Different applications require different mix designs: broom‑finished slabs for patios, higher PSI and deeper sections for driveways, and thicker edge beams for structures.

-

Controlled curing: Curing is controlled to avoid early surface shrinkage or dusting.

These details reflect a commitment to building driveways that last. CCM also lists its service areas—including Magnolia, Pinehurst, Stagecoach, Rose Hill, Decker Prairie, Tomball, Conroe and Lake Windcrest—which indicates that they understand the varied soil conditions across Montgomery County. Their driveway page highlights experience, use of 3500 PSI concrete and 3/8 in rebar, attention to detail, personalised design and unique finishes.

Maintenance tips to extend driveway life

-

Seal regularly. Apply a high‑quality penetrating sealer every 3–5 years to protect against moisture intrusion and de‑icing salts.

-

Address drainage. Keep gutters clear and ensure downspouts direct water away from the driveway.

-

Control heavy loads. Avoid parking heavy construction equipment or fully loaded moving vans on residential driveways not designed for such loads.

-

Repair promptly. Fix hairline cracks as soon as they appear. Waiting allows water to seep in, potentially turning a simple repair into a replacement.

-

Clean and maintain joints. Remove weeds and debris from joints and reseal them to prevent root intrusion.

Final thoughts

Deciding between repairing and replacing a concrete driveway in Magnolia requires evaluating crack width and depth, the condition of the subbase, and the age of the slab. Hairline cracks and small surface defects can usually be sealed or stitched. More significant cracks or widespread deterioration often indicate it is time for partial‑depth patching or full replacement. The hot, humid climate and expansive soils in Magnolia add complexity, making proper construction practices—such as compacting clay subgrades, installing a granular base, using 3,500 PSI concrete and rebar, and controlling curing—essential for long‑lasting driveways. Local expertise from contractors like CCM, who tailor their methods to Magnolia’s soil and climate, can maximise your investment and ensure a driveway that withstands the test of time. For a full list of services and options, visit CCM’s concrete services page.