Concrete Contractor Magnolia explains, step by step, how a patio extension stays level, drains cleanly, and supports Texas‑sized outdoor living.

Local climate and soil insight

Montgomery County clay expands when saturated and shrinks during midsummer heat. A patio extension must float on that shifting ground without cracking. Drainage paths, sun exposure, and tree‑root zones are mapped before the first shovel turns dirt. The result: consistent slab performance through spring storms and triple‑digit afternoons.

Quick thought: Mark any puddle spots after heavy rain; those notes guide slab elevation.

Selecting a 3500 PSI mix

A 3500 PSI concrete blend resists freeze–thaw cycles and surface abrasion far better than basic 2500 PSI pours. Higher cement content, clean aggregates, and an optimal water‑cement ratio keep shrinkage low. A cross‑tied 3/8″ rebar grid spreads loads and locks each panel together for decades of service.

Structural design for long life

-

Vibration‑tolerant base — Four inches of compacted crushed limestone under every slab limit settlement.

-

Rebar grid — #3 bars spaced 16″ on center carry lawn‑mower, smoker, and guest loads with ease.

-

Control‑joint pattern — Scored every eight feet in both directions to guide shrinkage cracks below the surface.

-

Perimeter thickness bump — Edges thicken to five inches where patios step away from foundations, countering cantilever stress.

Consider this: Heavy stone fire pits call for the five‑inch edge option.

Site preparation: from sod to sub‑base

-

Utility locates are cleared through 811 before excavation.

-

Laser levels map the final elevation—finish grade ends one inch below door thresholds.

-

Excavation removes sod and topsoil to the depth of slab thickness plus base.

-

Compaction reaches 95 % modified Proctor density, stopping future voids.

-

A 6‑mil moisture barrier blocks upward vapor and limits early‑age curling.

Reinforcement grid and formwork

Steel sits on two‑inch chairs so concrete fully envelops the grid. Straight pine boards keep corners square within a quarter inch over thirty feet. A water‑based release agent coats forms for crisp panel faces—no oily residue on surrounding soil.

Placement, finishing, and jointing

Concrete enters forms within 90 minutes of batching. A boom chute reduces splatter on landscape beds. After screeding, the crew bull‑floats once, then waits until sheen fades before edging and broom finishing. A medium‑texture drag gives shoes and paws reliable grip without roughness.

During hot August placements, a light evaporation retarder mist keeps surface water loss in check, eliminating plastic shrinkage cracks.

Curing timeline and first‑year care

| Day | Action | Purpose |

|---|---|---|

| 0–1 | 28 % solids curing compound | Locks moisture for full hydration |

| 2–7 | Foot traffic allowed | No rolling loads yet |

| 7–28 | Light garden cart OK | Strength climbs to 70 % of design |

| 28+ | Ready for outdoor kitchen install | Full 3500 PSI reached |

Long‑term maintenance stays simple: sweep grit, rinse with low‑pressure water, and reseal every three years.

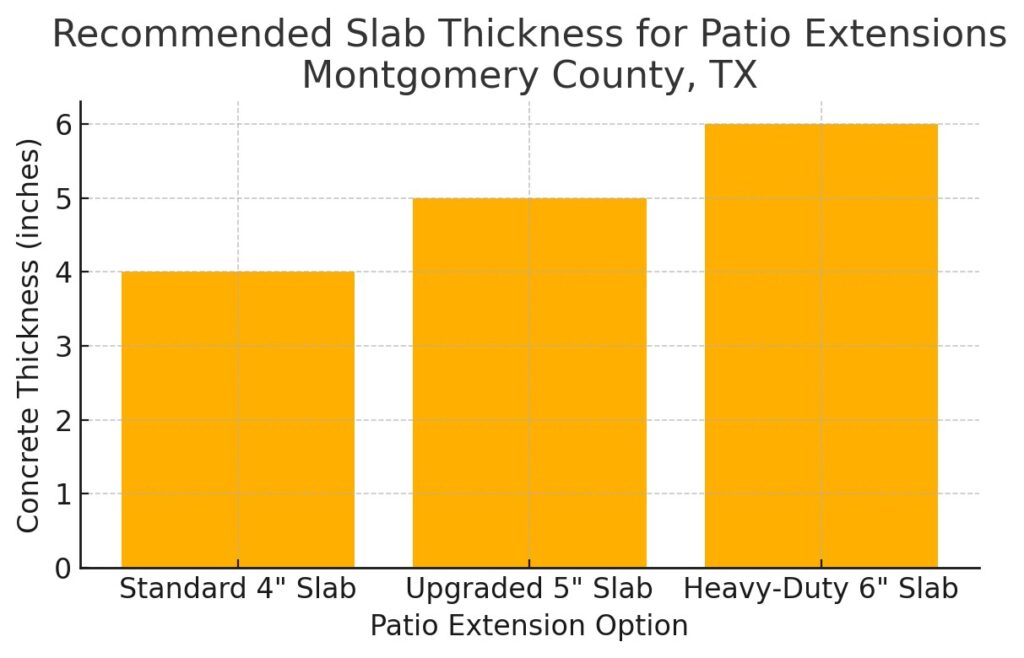

Cost, thickness, and value chart

The chart compares three slab options. A thicker section costs slightly more per square foot yet postpones replacement by a decade or longer—solid value for homeowners planning permanent outdoor living zones.

Frequently asked questions

Why choose rebar instead of wire mesh?

Bar steel delivers predictable tensile strength and keeps crack widths hairline small. Mesh often sinks during the pour, leaving little reinforcement where the slab needs it most.

Is a 3500 PSI mix necessary for a patio?

Yes. Higher strength translates to abrasion resistance. Patio furniture legs, grill casters, and dropped tools barely scratch a 3500 PSI surface; weaker mixes erode quickly.

What finish choices are available?

Standard broom, stamped texture, or exposed aggregate—all built on the same structural backbone. Finish changes appearance only.

How does drainage tie into design?

A one‑eighth inch per foot slope directs water away from the house, preventing pooling and soil heave.

For more answers, view the Concrete FAQ.

Start a project

See project photos and planning tips on the dedicated patio and porch service page. Ready to add a new concrete patio extension in Montgomery County? Call 713‑681‑4343 or use the contact form to schedule a free on‑site estimate.