Introduction

Full broadcast epoxy floors stand out for their unparalleled durability, aesthetic versatility, and functional advantages. These floors have become a preferred choice for both residential and commercial spaces due to their ability to withstand heavy traffic, resist chemical spills, and provide a customizable appearance. This comprehensive guide will explore the various aspects of full broadcast epoxy floors, including their benefits, applications, installation process, maintenance, and customization options, all while integrating rich anchor text from various sources to enhance the article’s depth and SEO.

What is a Full Broadcast Epoxy Floor?

A full broadcast epoxy floor is a type of epoxy flooring that involves spreading decorative flakes, chips, or quartz granules across a wet epoxy layer. This method not only enhances the visual appeal of the floor but also provides a slip-resistant texture, making it safer for high-traffic areas. The flakes come in various colors and sizes, allowing for extensive customization to match any interior design.

Benefits of Full Broadcast Epoxy Floors

- Durability: Full broadcast epoxy floors are renowned for their robustness. They can withstand significant wear and tear, making them ideal for areas with heavy foot or vehicle traffic. This durability is particularly beneficial in settings such as aircraft hangars and garage floors, where the floor must endure constant use and heavy loads.

- Aesthetic Appeal: The decorative flakes used in full broadcast epoxy floors are available in a myriad of colors and patterns. This variety allows for a high degree of customization, enabling homeowners and business owners to create unique and visually appealing flooring designs that complement their space.

- Safety: One of the primary advantages of full broadcast epoxy floors is their slip-resistant surface. The broadcast flakes create a textured finish that enhances traction, reducing the risk of slips and falls. This feature is especially important in environments like kitchen floors and pool decks, where moisture can make floors slippery.

- Chemical Resistance: Epoxy floors are highly resistant to a wide range of chemicals, making them suitable for industrial environments where spills are common. This resistance ensures that the floor maintains its integrity and appearance over time, even in harsh conditions.

- Ease of Maintenance: Maintaining a full broadcast epoxy floor is straightforward. The seamless surface prevents dirt and debris from accumulating in cracks or crevices, making it easy to clean. Regular sweeping and occasional mopping with a mild detergent are usually sufficient to keep the floor looking pristine.

Applications of Full Broadcast Epoxy Floors

Residential Applications

In residential settings, full broadcast epoxy floors are an excellent choice for various areas, including garages, kitchens, living rooms, and basements. Their durability and resistance to staining make them ideal for high-traffic and high-use areas. Additionally, the ability to customize the look of the floor allows homeowners to create a cohesive design throughout their home.

Garages

Garage floors often endure heavy loads and exposure to oil, grease, and other automotive fluids. A full broadcast epoxy floor provides a robust and easy-to-clean surface that can withstand these challenges. The decorative flakes also add a touch of style to what is typically a utilitarian space.

Kitchens

In kitchens, floors are subjected to frequent spills, dropped utensils, and high foot traffic. The slip-resistant and easy-to-clean nature of full broadcast epoxy floors makes them an ideal choice for this area. The variety of design options also allows for a seamless integration with the overall kitchen decor.

Living Rooms

For living rooms, the aesthetic versatility of full broadcast epoxy floors is a significant advantage. Homeowners can choose from a wide range of colors and patterns to create a floor that complements their interior design. The durability of epoxy floors also means they can handle the wear and tear of daily life, including pet traffic and furniture movement.

Commercial Applications

Commercial spaces, such as restaurants, aircraft hangars, workshops, and retail stores, benefit greatly from the features of full broadcast epoxy floors. These environments require flooring that can endure high traffic, frequent cleaning, and, in some cases, exposure to chemicals or heavy equipment.

Restaurants

In a restaurant setting, floors must be both attractive and functional. Full broadcast epoxy floors meet these requirements by providing a slip-resistant surface that is easy to clean and maintain. The ability to customize the design also allows restaurant owners to create a welcoming and stylish environment for their patrons.

Aircraft Hangars

Aircraft hangars require floors that can support the weight of aircraft and withstand exposure to fuel, oil, and other chemicals. Full broadcast epoxy floors provide the necessary durability and chemical resistance, ensuring a safe and long-lasting surface. The smooth, seamless finish also makes it easy to spot and clean up spills quickly.

Workshops

Workshops often involve heavy machinery, tools, and materials that can damage traditional flooring. Full broadcast epoxy floors offer a resilient and easy-to-clean surface that can handle the demands of a busy workshop. The slip-resistant texture also enhances safety for workers.

Industrial Applications

In industrial settings, full broadcast epoxy floors are used in workshops and warehouses due to their ability to withstand heavy machinery and frequent traffic. The chemical resistance of epoxy floors also protects against spills and stains, ensuring a long-lasting and safe working environment.

Warehouses

Warehouse floors must endure the constant movement of forklifts, pallets, and heavy inventory. Full broadcast epoxy floors provide a durable and low-maintenance solution that can withstand this heavy use. The seamless surface also makes it easy to keep the warehouse clean and organized.

Manufacturing Plants

Manufacturing plants often deal with spills, heavy equipment, and foot traffic. Full broadcast epoxy floors offer the necessary durability and chemical resistance to maintain a safe and functional environment. The slip-resistant texture also reduces the risk of accidents, contributing to overall workplace safety.

Installation Process

Installing a full broadcast epoxy floor involves several key steps to ensure a smooth and durable finish:

Surface Preparation

Proper surface preparation is crucial for the successful installation of a full broadcast epoxy floor. The existing floor must be thoroughly cleaned, and any cracks or imperfections repaired. This may involve concrete finishing, polishing, or texturing to create an ideal surface for the epoxy to adhere to. Surface preparation typically includes the following steps:

- Cleaning: Remove all dirt, grease, oil, and other contaminants from the floor. This step ensures that the epoxy adheres properly to the concrete surface.

- Repairing: Fill any cracks, holes, or imperfections in the concrete. This step creates a smooth and even surface for the epoxy coating.

- Profiling: Use mechanical methods, such as grinding or shot blasting, to create a rough surface profile. This step enhances the adhesion of the epoxy to the concrete.

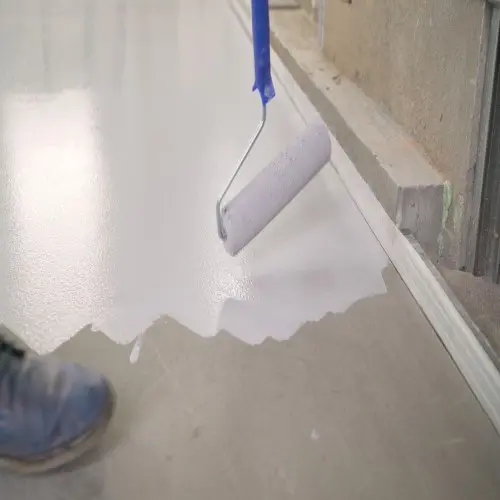

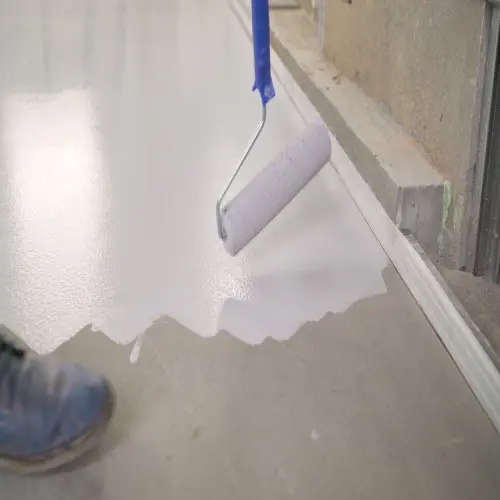

Priming

After surface preparation, a primer is applied to enhance the adhesion of the epoxy coating to the concrete substrate. The primer also helps to seal the concrete, preventing air bubbles from forming in the epoxy layer. This step involves:

- Mixing the Primer: Follow the manufacturer’s instructions to mix the primer components.

- Applying the Primer: Use a roller or brush to apply the primer evenly across the surface. Ensure complete coverage to avoid any weak spots.

- Allowing to Cure: Let the primer cure according to the manufacturer’s recommended curing time before proceeding to the next step.

Epoxy Application

Once the primer has cured, the first layer of epoxy is applied to the primed surface. This layer serves as the base for the broadcast flakes. The epoxy application process includes:

- Mixing the Epoxy: Combine the epoxy resin and hardener according to the manufacturer’s instructions.

- Applying the Epoxy: Use a roller or squeegee to spread the epoxy evenly across the floor. Ensure a consistent thickness to avoid uneven curing.

- Allowing Initial Cure: Let the epoxy sit for a specified period (usually 10-20 minutes) to begin the curing process before broadcasting the flakes.

Broadcasting Flakes

While the epoxy is still wet, decorative flakes are evenly spread across the surface. This step requires precision to ensure a uniform distribution. The broadcasting process includes:

- Selecting Flakes: Choose the desired color and size of flakes based on the design preferences.

- Broadcasting Technique: Throw the flakes upward and let them fall onto the wet epoxy. This technique ensures even coverage and prevents clumping.

- Allowing to Cure: Let the epoxy and flakes cure completely, typically for 24 hours, before proceeding to the next step.

Topcoat Application

After the base layer has cured, a clear topcoat is applied to seal the flakes and provide a smooth, durable finish. The topcoat application process includes:

- Mixing the Topcoat: Combine the topcoat components according to the manufacturer’s instructions.

- Applying the Topcoat: Use a roller or brush to apply the topcoat evenly across the surface. Ensure full coverage to protect the underlying flakes.

- Allowing Final Cure: Let the topcoat cure for the recommended time before allowing foot or vehicle traffic on the floor.

Maintenance and Care

Maintaining a full broadcast epoxy floor is straightforward and involves regular cleaning to keep the surface free of dirt and debris. Proper maintenance ensures the floor’s longevity and aesthetic appeal. For best results:

Regular Cleaning

- Sweeping or Vacuuming: Sweep or vacuum the floor regularly to remove dust, dirt, and debris. This step prevents abrasive particles from scratching the surface.

- Mopping: Use a mild detergent solution to mop the floor periodically. Avoid using harsh chemicals or abrasive cleaning tools that could damage the epoxy coating.

- Spot Cleaning: Address spills and stains promptly to prevent them from setting into the epoxy. Use a soft cloth or mop and a gentle cleaner for spot cleaning.

Preventive Measures

- Use Floor Mats: Place floor mats at entrances to reduce the amount of dirt and moisture brought onto the epoxy floor. This step is especially useful in high-traffic areas such as restaurant entrances and workshop floors.

- Protective Pads: Use protective pads under furniture legs and heavy equipment to prevent scratches and indentations on the epoxy surface.

- Avoid Harsh Chemicals: While epoxy floors are chemically resistant, it’s best to avoid prolonged exposure to harsh chemicals. Clean any chemical spills immediately to prevent potential damage.

Periodic Maintenance

- Re-Coating: Depending on the traffic and wear, the epoxy floor may require re-coating every few years to maintain its appearance and protective qualities. This involves lightly sanding the surface and applying a new topcoat.

- Inspection: Regularly inspect the floor for any signs of wear, damage, or peeling. Early detection allows for timely repairs, preventing more extensive damage.

Customization Options

One of the most significant advantages of full broadcast epoxy floors is the ability to customize the appearance to suit any space. Various colors and flakes can be mixed to create unique patterns and designs, ensuring the flooring complements the overall aesthetic of the space. This customization can include:

Color Selection

- Single Colors: Choose a single color for a clean and uniform look. This option is often used in commercial spaces for a professional appearance.

- Multi-Color Blends: Combine multiple colors of flakes to create intricate patterns and designs. This is ideal for residential applications where a more decorative touch is desired.

Flake Sizes

- Small Flakes: Smaller flakes provide a more subtle texture and are often used in residential settings.

- Large Flakes: Larger flakes create a more pronounced texture, suitable for industrial and commercial environments where slip resistance is a priority.

Patterns and Designs

- Random Broadcast: Flakes are spread randomly across the surface for a natural, speckled look.

- Custom Patterns: Create custom patterns and designs by selectively broadcasting flakes in specific areas. This technique can be used to create logos or other unique designs, particularly in commercial settings.

Enhancements

- Metallic Epoxy: Incorporate metallic pigments into the epoxy to create a shimmering, high-gloss finish. This option adds a luxurious touch to residential and commercial spaces alike.

- Glow-in-the-Dark Flakes: Add glow-in-the-dark flakes for a unique and functional enhancement. This feature is useful in areas where low-light visibility is important, such as pool decks and workshops.

Related Flooring Solutions

In addition to full broadcast epoxy floors, several other concrete flooring solutions are available, each with its own set of benefits. Understanding these options can help you make an informed decision about the best flooring solution for your needs:

Concrete Coatings

Concrete coatings involve applying a protective layer over the concrete surface to enhance its durability and appearance. These coatings can include epoxy, polyurethane, and acrylic, each offering different levels of protection and aesthetic appeal.

Decorative Concrete

Decorative concrete techniques such as staining, texturing, and polishing are used to enhance the appearance of concrete floors. These techniques can create various effects, from subtle color changes to intricate patterns, making concrete a versatile flooring option.

Sealed Concrete

Sealed concrete involves applying a protective sealant to the concrete surface to prevent staining and enhance durability. This option is ideal for areas where a natural concrete look is desired but additional protection is needed.

Stained Concrete

Stained concrete uses acid-based or water-based stains to add color and design to concrete floors. This technique can create a wide range of looks, from translucent shades to vibrant, opaque colors.

Sidewalk Coatings

Sidewalk coatings improve the durability and appearance of sidewalks, making them more resistant to weather and wear. These coatings can also enhance slip resistance, improving safety for pedestrians.

Conclusion

Full broadcast epoxy floors offer a perfect blend of durability, aesthetics, and functionality, making them an excellent choice for a variety of applications. Whether in a residential garage, a commercial kitchen, or an industrial workshop, these floors provide a long-lasting, attractive solution that stands up to the demands of high-traffic environments.

The benefits of full broadcast epoxy floors—such as their durability, aesthetic versatility, and ease of maintenance—make them a superior choice for many settings. The customization options allow for unique and personalized designs, ensuring the floor complements the overall aesthetic of the space. Proper installation and maintenance ensure that these floors remain in excellent condition for years to come.

For more information on full broadcast epoxy floors and other concrete flooring solutions, visit Epoxy Garage Floor, a leading provider of high-quality epoxy flooring systems. Additionally, explore specific applications and related flooring solutions through the following resources:

- Epoxy Flooring

- Aircraft Hangars

- Garage Floors

- Kitchen Floors

- Living Room Floors

- Pool Deck

- Restaurant

- Workshop Floors

- Concrete Finishing

- Concrete Coatings

- Concrete Polishing

- Concrete Texturing

- Decorative Concrete

- Sealed Concrete

- Sidewalk Coatings

- Stained Concrete

- Colors & Flake

- Residential

- Commercial

- Gallery

- Blog

- Full Flake Epoxy Broadcast

- Contact

By exploring these resources, you can gain a deeper understanding of the benefits and applications of epoxy flooring and related solutions, ensuring that you make an informed decision for your next flooring project.